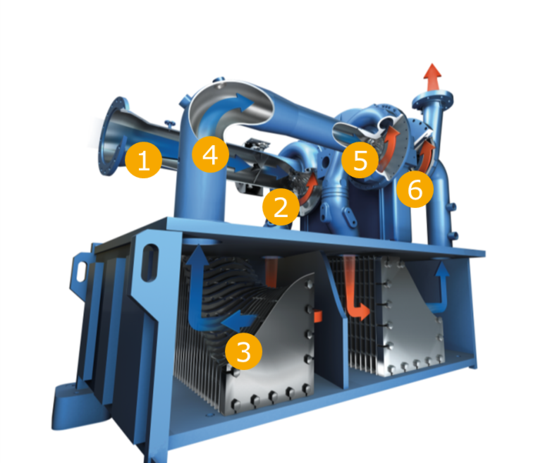

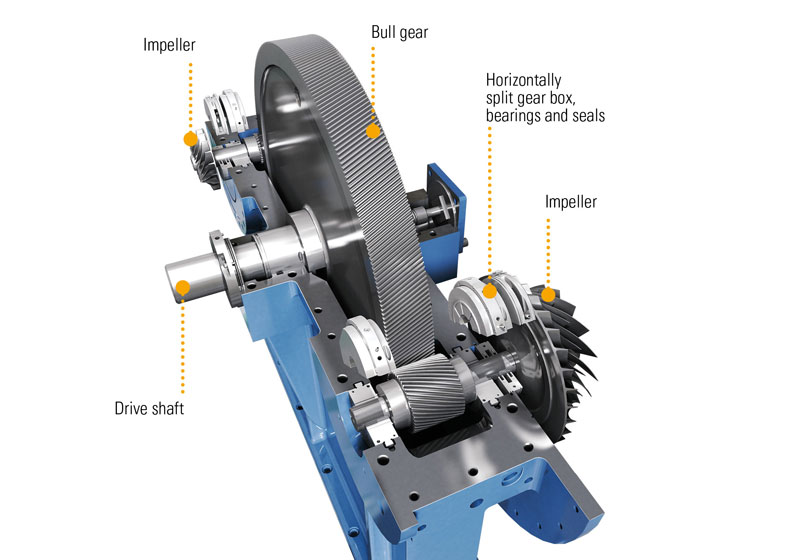

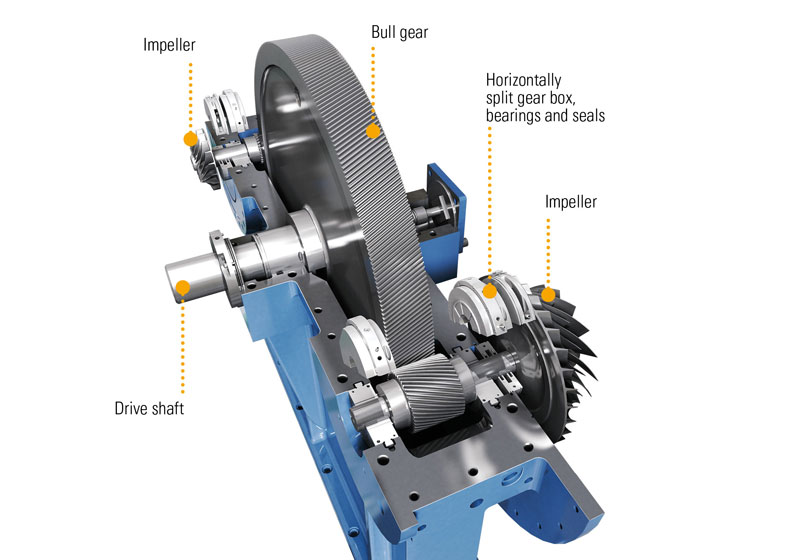

Turbo compressor DYNAMIC P - Three-stage, oil-free compressors for 100% oil-free compressed air at low energy costs.

| Product Code : | Bizimle İletişime Geçin |

| Category : | Turbo Compressors |

Turbo compressor DYNAMIC P - Three-stage, oil-free compressors for 100% oil-free compressed air at low energy costs.